Fidar System & Acrylic Clear Sheets in Canada: A Comprehensive Guide

Introduction

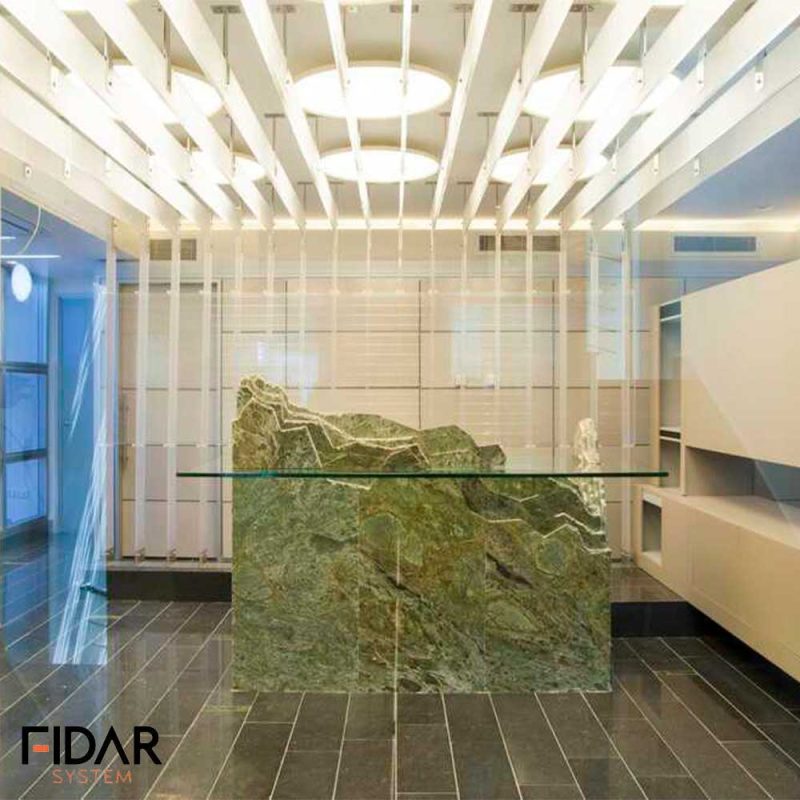

Fidar System Inc. (also styled “FIDARsystem” or “Fidar System”) is a well-established Canadian distributor and supplier of premium plastic and architectural sheet materials. Their product line includes cast acrylic sheets, polycarbonate panels, PVC foam boards, and aluminum composite sheets, making the company a trusted partner for a wide range of industries.

With more than 15 years of continuous experience, Fidar System has built a reputation for reliability, technical expertise, and customer service. The company supports designers, architects, builders, manufacturers, and signage businesses by providing not only top-quality materials but also value-added services such as custom cutting, drilling, bending, and fabrication.

This article offers a comprehensive look at acrylic clear sheets Canada—covering their definition, unique properties, technical advantages, practical applications, buying considerations, and the ways in which Fidar System helps customers across the country find the right solutions for their projects.

But here’s the catch: not all acrylic sheets are created equal. Prices, durability, and applications can vary a lot depending on the type you choose and where you buy it. This guide is designed to give you everything you need—facts, comparisons, and actionable tips—so you can make the right choice for your next project.

What Is Cast Clear Acrylic?

Cast acrylic, also known as plexiglass, Perspex, or PMMA (polymethyl methacrylate), is a transparent thermoplastic produced by pouring liquid monomer into molds and curing it under carefully controlled conditions. This casting process creates sheets with exceptional clarity, consistent thickness, and higher surface hardness compared to extruded acrylic.

Because of its superior manufacturing method, cast acrylic does not suffer from the internal stresses often found in extruded sheets. This makes it more stable, less prone to warping, and better suited for laser cutting, polishing, and precision fabrication. Its optical clarity allows it to transmit over 92% of visible light, making it even clearer than many types of glass.

Key Technical Properties of Cast Acrylic:

- High transparency and optical clarity – maintains crystal-clear appearance.

- Strong impact resistance – approximately 10–12 times stronger than ordinary glass.

- Lightweight – about half the weight of glass, making it easier to handle and install.

- Wide temperature tolerance – performs well in environments ranging from -40°C to +90°C.

- Excellent weather resistance – when UV-stabilized, resists yellowing and maintains durability outdoors.

- Versatility in fabrication – can be cut, drilled, thermoformed, glued, or laser-engraved without losing clarity.

Because of these features, cast acrylic has become the material of choice for industries that require durability, optical performance, and design flexibility.

Types of Clear Acrylic Sheets

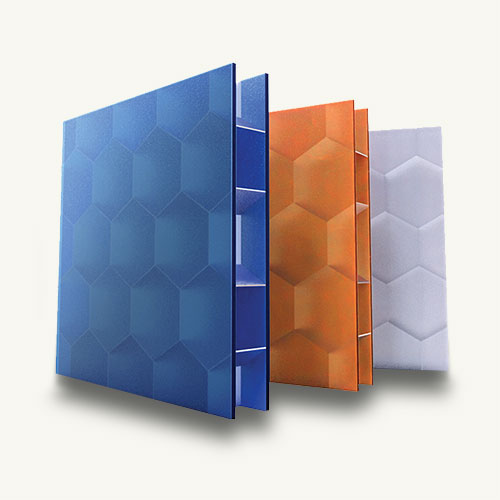

Clear acrylic sheets are available in several variations, each engineered to meet specific needs. Understanding the differences helps buyers choose the right material for their project:

- Cast Acrylic

Produced by pouring liquid acrylic into molds, cast acrylic provides premium clarity, higher surface hardness, and excellent long-term durability. It is ideal for projects that demand precision, such as display cases, aquariums, architectural glazing, and laser-cut signage. - Extruded Acrylic

Manufactured by pushing melted acrylic through a die, extruded sheets are less expensive and easier to cut or thermoform. While they are suitable for many general-purpose uses, they may show slight thickness variations and are less stable under heat compared to cast acrylic. Common applications include protective covers, indoor signage, and DIY projects. - UV-Resistant Acrylic

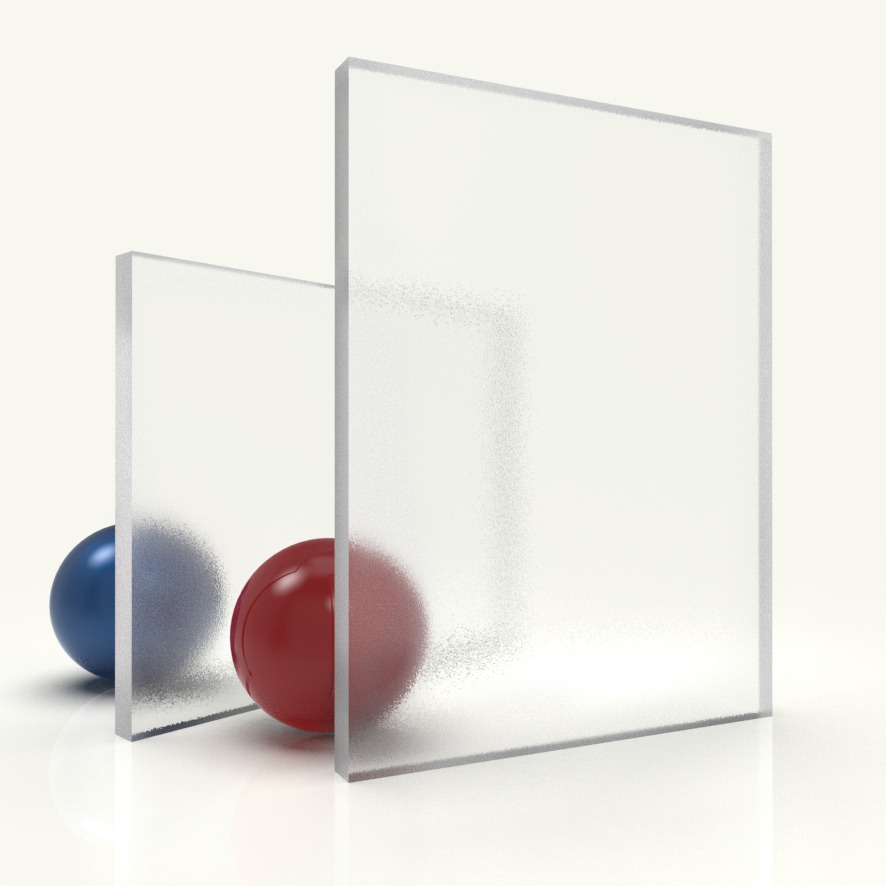

Specifically formulated to withstand prolonged exposure to sunlight, these sheets resist yellowing and brittleness outdoors. They are often used for greenhouses, outdoor signage, skylights, and patio enclosures, where clarity and weather-resistance are essential. - Frosted or Opal Acrylic

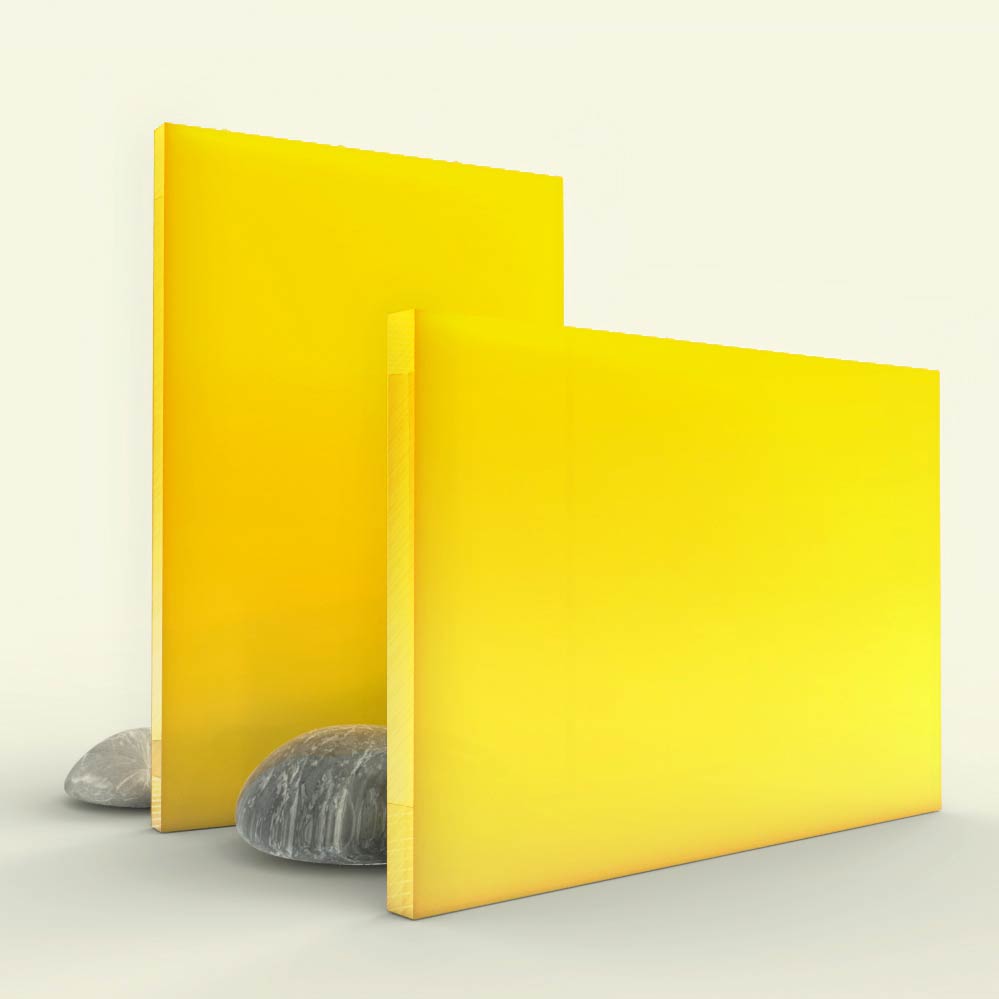

These sheets diffuse light and reduce glare, offering privacy and aesthetic appeal. Frosted acrylic is popular for office partitions, decorative panels, light diffusers, and retail displays where a soft, modern look is desired. - Tinted or Mirror Acrylic

Available in various colors or with reflective finishes, these sheets are used in advertising, point-of-sale displays, interior design, and creative architectural elements. Tinted options filter light, while mirrored acrylic serves as a lightweight, shatter-resistant alternative to glass mirrors.

Fidar’s Acrylic & Material Portfolio

Fidar System offers one of the most comprehensive selections of acrylic and architectural sheet materials in Canada. Their portfolio is designed to meet the needs of industries ranging from construction and signage to interior design and retail displays.

Key highlights include:

- Wide Thickness Range: From ultra-thin 2 mm sheets for lightweight applications to heavy-duty 30 mm sheets for structural or protective use.

- Variety of Finishes: Options include clear, tinted, pastel-colored, frosted, and mirror finishes, providing flexibility for both functional and decorative projects.

- Trusted Brand Partnerships: Fidar distributes HHC cast acrylic sheets from Taiwan, known for their superior optical quality and durability.

- Alternative Materials: In addition to acrylic, Fidar also supplies polycarbonate sheets (impact-resistant), PVC foam panels (lightweight signage and displays), and aluminum composite panels (modern cladding and architectural finishes).

- Convenient Delivery: Free shipping is available within the Greater Toronto Area (GTA), supported by a fully stocked warehouse located at Unit 29, 601 Magnetic Drive, North York, Ontario.

Beyond raw material supply, Fidar adds value with custom fabrication services, including:

- Precision cut-to-size orders to minimize waste

- Drilling and edge finishing for ready-to-install components

- Bending and thermoforming for architectural and retail designs

- Consultation support to help customers select the best material for their projects

Buying Clear Acrylic Sheets in Canada

Before purchasing acrylic sheets, it’s important to evaluate several practical factors:

- Dimensions & Thickness: Standard sheet sizes are typically 48″ × 96″ (4 × 8 ft), but Fidar provides flexible sizing through custom cutting. Choose thickness based on intended use (e.g., thin sheets for covers vs. thicker sheets for structural barriers).

- Local Availability: While Fidar ships nationwide, many customers still search “clear acrylic sheets near me” for convenience and faster turnaround. Local delivery in GTA ensures shorter lead times.

- Quality: Look for optical-grade sheets with UV-stabilization to ensure long-lasting clarity, especially for outdoor use.

- Shipping & Handling: Acrylic requires proper packaging to prevent scratches, edge chipping, or warping. Fidar uses protective films and reinforced packaging for secure transit.

- Applications: Clear acrylic sheets are suitable for a wide range of uses, including retail displays, protective barriers, skylights, furniture elements, partitions, and industrial machine guards.

Applications of Clear Acrylic Sheets

Clear acrylic sheets are versatile materials that have found applications across many industries in Canada thanks to their combination of light weight, transparency, and durability. Some of the most common and valuable uses include:

- Architecture & Construction

Used as skylights, partitions, balcony enclosures, canopies, and protective wall panels. Clear acrylic is an ideal substitute for glass in architectural projects where safety, ease of installation, and resistance to shattering are important. - Retail & Advertising

Frequently chosen for display cases, illuminated signage, point-of-purchase displays, and promotional stands. Retailers rely on acrylic to showcase products attractively while maintaining a lightweight, durable structure. - DIY & Home Projects

Popular among homeowners and hobbyists for greenhouses, furniture overlays, shelves, picture frames, and window replacements. Its ease of cutting and shaping makes it suitable for a wide variety of custom projects. - Industrial Applications

Utilized in machine guards, equipment covers, safety panels, and light diffusers. In factories and workshops, acrylic offers a clear view of equipment operation while protecting workers from moving parts. - Specialty Uses

Thick cast acrylic sheets are commonly used for aquariums, terrariums, exhibition enclosures, and museum displays. The material’s strength and clarity allow for safe, long-term installations that maintain visibility and aesthetic appeal.

Advantages and Limitations of Clear Acrylic

✔️ Advantages

- Lightweight and easy to fabricate – half the weight of glass, simple to cut, drill, or bend.

- Excellent clarity – maintains optical transparency close to or even better than standard glass.

- Good impact resistance – about 10 times stronger than ordinary glass.

- Long service life – especially when UV-stabilized for outdoor applications.

- Versatility – suitable for both decorative and functional projects.

⚠️ Limitations

- Prone to scratches – the surface can be marked more easily than glass; protective coatings or careful cleaning are recommended.

- Less impact-resistant than polycarbonate – while stronger than glass, it is not as tough as polycarbonate sheets.

- Sensitive to improper handling – can crack under stress or yellow over time if exposed to UV without protection.

Installation & Care

Proper installation and maintenance are key to ensuring the long life and performance of clear acrylic sheets. Here are some essential tips:

- Cutting & Fabrication: Use fine-tooth saws, routers, or laser cutters to achieve smooth edges without cracking. Always leave the protective film on during cutting to prevent surface damage.

- Drilling: When drilling, use specialized acrylic drill bits or go at slow speeds to avoid stress fractures. Support the sheet on a flat surface to minimize vibration.

- Cleaning: Wash with mild soap and lukewarm water, and avoid strong solvents such as acetone or ammonia-based cleaners, which can damage the surface.

- Scratch Prevention: Use microfiber or soft cotton cloths to reduce scratches. For long-term protection, consider applying an anti-scratch coating.

- Installation: Keep the protective masking film on until final assembly to prevent accidental damage during handling.

- Storage: Always store sheets flat in a cool, dry area to prevent bowing or warping. Avoid stacking heavy objects on top.

- Outdoor Use: For exterior applications, always select UV-stabilized acrylic to maintain clarity and avoid yellowing over time.

FAQs (Frequently Asked Questions)

Is Fidar System a reliable supplier of cast clear acrylic in Canada?

Yes. With more than 15 years of experience and a warehouse in North York, Ontario, Fidar System is recognized as a trusted supplier.

What thicknesses of clear acrylic does Fidar offer?

Fidar provides sheets ranging from 2 mm to 30 mm, including clear, tinted, pastel, and mirror finishes.

Does Fidar provide custom fabrication?

Yes. Services include cut-to-size, drilling, edge finishing, and bending to meet project requirements.

Can I find clear acrylic sheets “near me” using Fidar?

Yes. Fidar ships nationwide, but local customers in GTA benefit from faster, free shipping.

Will acrylic sheets yellow outdoors?

UV-stabilized cast acrylic resists yellowing and can retain clarity for 10–15 years in outdoor environments.

How does acrylic compare to cheaper plastics?

Cast acrylic maintains clarity and durability longer, while low-grade plastics may warp, discolor, or scratch easily.

Can acrylic sheets be laser cut?

Yes. Cast acrylic is ideal for laser cutting, producing smooth, polished edges.

Are acrylic sheets recyclable in Canada?

Yes. PMMA (acrylic) can be recycled, but recycling availability varies by province.

Are acrylic sheets safe for aquariums or food displays?

Yes. Thick cast acrylic is commonly used in aquariums, while food-grade acrylic is available for hygienic food display applications.

Can acrylic sheets be painted or printed on?

Yes. Acrylic can be screen-printed, UV-printed, or painted with compatible paints, making it popular in signage and advertising.