PMMA FOR AVIATION

From ultralight planes to helicopters and massive commercial aircraft, the materials used in the construction of airplanes must endure extreme stress levels. In order to be considered suitable, the objects or products should possess the capabilities of providing immense flexibility in design, enduring variations in temperature, while being as lightweight as possible. One of the primary hurdles to overcome involves achieving weight reduction to save fuel, while ensuring safety measures are not compromised.

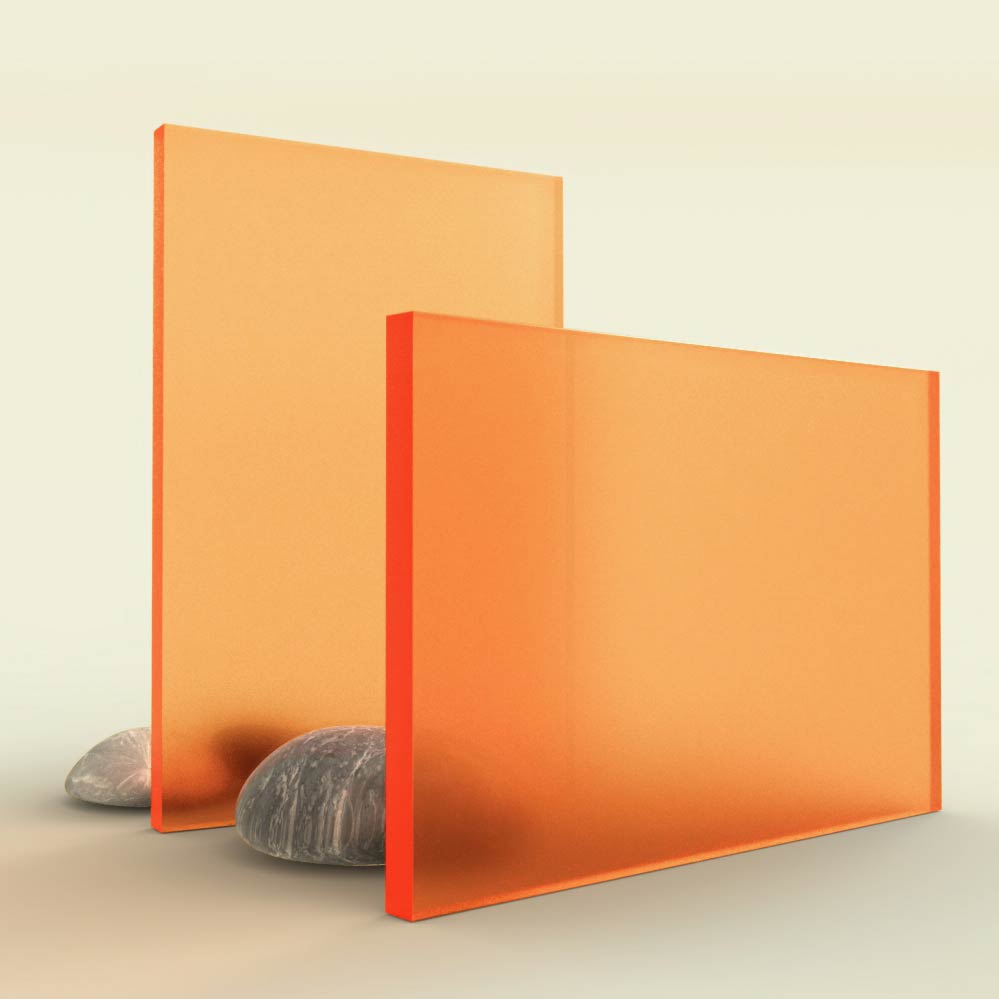

PLEXIGLAS® and EUROPLEX® are at the forefront of acrylic technology and have cutting-edge sheet manufacturing facilities. They have joined forces to cater to the aviation markets by providing aircraft transparencies and fulfilling the interior demands of aircrafts. PLEXIGLAS® offers a comprehensive range of sheet products that are suitable for fulfilling the diverse requirements of windows and translucent elements in various types of aircraft, including helicopters, general aviation planes, commercial planes and military planes. EUROPLEX® sheet products are well received for use in aircraft interiors as they comply with a host of rigorous standards.

CUSTOM SOLUTIONS FOR ALL APPLICATIONS

Perfect for extensive indoor installations, these opaque panels are perfect as exterior coverings for walls, doors, and ceilings and come in an array of colors.

Outstanding measures are taken to ensure fire safety, accomplishing all FST criteria outlined by FAR 25.853 and ABD 0031, with compliance to the OSU Heat Release Test (FAR 25.853 (d)) as well.

The substance displays exceptional durability when utilized in a consistent manner under extremely high temperatures, with mechanical abilities remaining intact up to 190°C.

Tailored to meet high-altitude demands.

Regardless of the type of aircraft, whether it be a small ultralight, a helicopter or a large commercial airplane, the construction materials utilized must be able to endure extreme forces and pressures. They must endure unparalleled shifts in temperature, shield against severe UV exposure, exhibit strong capabilities against weather, and have resilience - and yet, maintain the lightest possible weight. One of the primary obstacles is to achieve fuel efficiency by reducing weight without compromising safety.

PLEXIGLAS® sheets were initially utilized for aircraft transparencies because of their featherweight nature, immunity to abrupt temperature changes, and remarkable features related to optical clarity and mechanical properties.

For numerous years, PLEXIGLAS® acrylic sheets have been extensively utilized in aircraft windows and other transparent structures.

ACM – Black Gloss + Black Matte – 0.3mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-G024+YT-Black/Blac-0.3-3

Login to see prices

ACM – Black Matte + Sea Blue – 0.2mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-024+YT--Black/Blue-0.2-3

Login to see prices

ACM – Mirror – 0.3mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-JM-001-Mirror-0.3-3

Login to see prices

ACM – White Matte + Brushed Silver – 0.2mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-M007+LS-White/Silv-0.2-3

Login to see prices

ACM – White Matte + Metallic Silver – 0.2mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-M007+YT-White/Silv-0.2-3

Login to see prices

ACM – White Matte + Postal Green – 0.2mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-M007+YT-White/Green-0.2-3

Login to see prices

ACM – White Matte + White Gloss – 0.3mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-M007+YT-White/Whit-0.3-3

Login to see prices

ACM – White Matte + White Matte – 0.2mm / 3mm – Face / Panel Thickness

SKU:

24WM0719-256-ACM-YT-M007+YT-White/Whit-0.2-3

Login to see prices

PROPS & APPS

High-quality aviation sheets are employed for various see-through uses, such as glazing, wing-tip lenses, and edge-lit-panels. PLEXIGLAS® sheets made specifically for aviation applications demonstrate the subsequent characteristics:

- The light transmission and brilliance are exceptionally

- Outstanding.

- Remarkable ability to resist weather conditions.

- The absolute capacity to recycle.

- Simplicity in production.The surface is highly resistant to indentations and scratches.

- The item's weight is exceptionally light, only half of that of glass.

- It is 11 times more durable than glass when it comes to withstanding shattering.

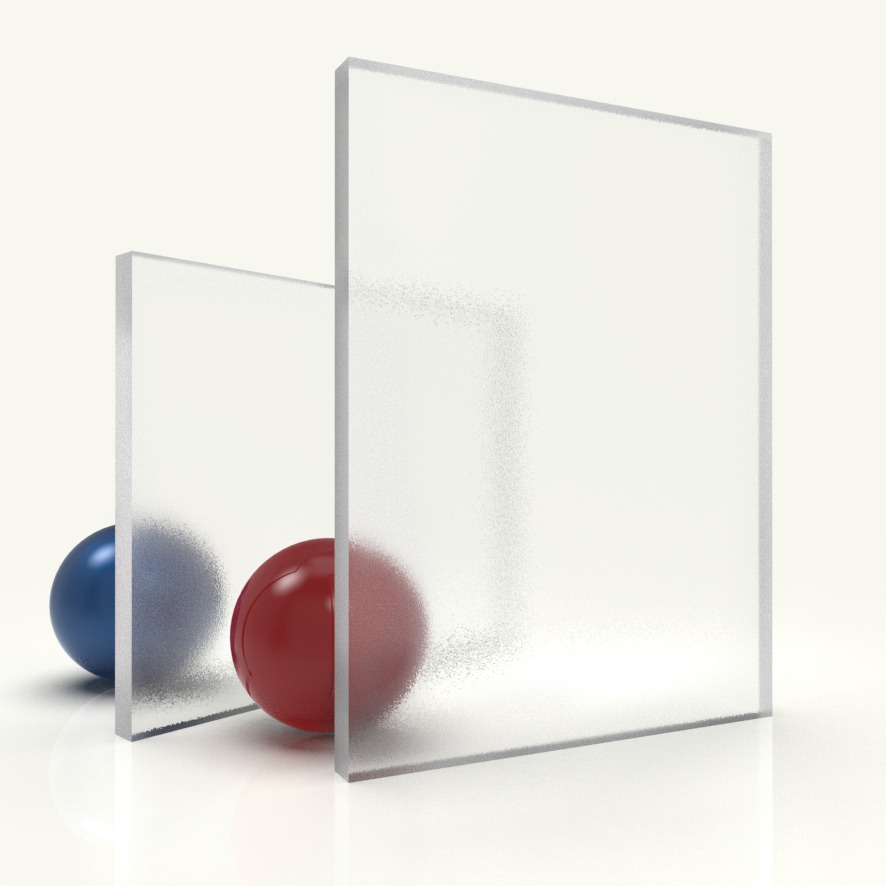

PLEXIGLAS® GS 245

PLEXIGLAS® GS 245 acrylic sheet is suitable and meets the required standards.

The AECMA 4364 and MIL-PRF-5425 are rules that specify how things should be made for airplanes. These rules are important in situations where it is very important to have high standards. These are rules for using in airplanes. It is of high quality and costs more than average.

Making sure that something is smooth and has the right measurements.

Please provide the original text to rewrite it in simple words.

Application means a program or software used on electronic devices like computers, smartphones, and tablets to perform specific tasks or functions.

Current uses of these things include the control panel in a vehicle and the outer end of an airplane wing.

Application

There are things called lenses, dust covers, helicopter bubbles, and aircraft canopies. PLEXIGLAS® GS 245 sheet is a type of material that is used in airplanes and other things that fly in space. See-through containers made of one or more layers. Making something from raw materials, usually in an industrial or manufacturing setting.

Fabrication

The way we make things out of regular acrylic material. This type of sheet is good for using with PLEXIGLAS® GS 245 sheet. achieved by carefully shaping and draping the material. If you heat up a sheet of material to 150°C all over, you can achieve something. This means the temperature is 160 degrees Celsius. For making shapes by applying pressure or removing air.

It is suggested to use a temperature range from 170 to 190 degrees Celsius.

Properties

The material doesn't let much ultraviolet light through (especially in the range of 290-330 nanometers). This means that something has met certain rules for airplanes and military equipment. It was also approved by the US Navy. This is a type of strong acrylic that can withstand different weather conditions very well. This was made specifically to fulfill the airplane industry's need for excellent optics.

PLEXIGLAS® Stretched

Plexiglas is a type of material made from stretched acrylic sheets.

It means that something has been approved by organizations called AECMA 4366 and MIL-PRF-25690.

PLEXIGLAS® Stretched is a better type of PLEXIGLAS®.

A special material called GS 249 that has been made stronger by connecting its molecules together. The pullable plastic called acrylic that has been expanded or elongated.

Makes it harder for cracks to form and for chemicals to damage.

It makes it work better.

Application

PLEXIGLAS® Stretched is a type of material that is used in many different things like airplanes and buildings. It can be made in one solid piece or put together with other pieces.

Fabrication

materials are not suitable for nanomaterials due to their small size. This means new and innovative methods must be developed to create nanomaterials in a lab. This means that nanomaterials cannot be made using the same techniques as regular materials because they are too small. New methods need to be created to make nanomaterials in a laboratory.

When making PLEXIGLAS® Stretched sheets, you could also use acrylic materials. Making a long and thin sheet out of acrylic requires special and advanced ways of working with it. be monitored carefully when creating objects out of metal.

The temperature should not go over 110°C and it will take longer to shape the object.

Unstretched acrylic is not as good as stretched acrylic.

Properties

- UV rays with a wavelength between 290-330 nm can only pass through less than 1% of the material.

- This means that the product has been approved and meets the standards for aviation safety according to AECMA 4366 and MIL-PRF-25690.

- This can better withstand the weather and other natural factors.

- This is made from a material called PLEXIGLAS® GS 249, which meets a certain standard called AECMA 4365.

- Mil-PRF-8184 is a set of specifications or rules that products in the military need to meet.

The glasses are really clear and are all the same size. Because the material was ground and polished. - This material is called MIL-PRF-25690 Class 2, and it can be used for something else. "Class 1 applications" means software programs that are used for basic tasks and are easy to use.

Regardless of the type of aircraft being considered, whether it be ultralight or commercial, the materials utilized in its construction must possess the utmost resilience to endure the most intense pressures. These objects must be able to endure drastic fluctuations in temperature, shield against powerful UV rays, display resistance to various weather conditions, and possess toughness - while maintaining a lightweight design. One of the primary hurdles is striking a balance between safety and weight reduction to achieve lower fuel consumption.

PLEXIGLASS sheets were initially used for aircraft transparencies owing to their exceptional optical clarity, mechanical characteristics, lightness, and thermal shock resistance.

PLEXIGLASS acrylic sheets have been widely utilized in aircraft windows over the years.