Plexiglas, Popular Material or Health Enemy: The Potential Health Risks of Plexiglass: A Comprehensive Review

Introduction to Plexiglass and its Increasing Use in Various Settings

Lots of plastics use plasticizers to make them flexible but these can evaporate over time and become a health hazard. However, at FIDARSYSTEM, Our product won’t release any of its components into the environment, so there’s no need to worry about any smells. It meets all the standards for its environmental and health impact, no matter what it’s being used for.

FIDARSYSTEM products doesn’t have any plasticizers, heavy metal salts, chlorine, nitrogen’s, or aromatics, and you don’t need much, if any, additives.

As far as we know, it doesn’t release anything toxic, cancer-causing, or mutagenic, not even at its melting point of around 100°C. Plus, it doesn’t put any chemicals into the air, water, or ground, and it doesn’t emit any toxic fumes if it catches fire.

Hamid Ali “CEO”

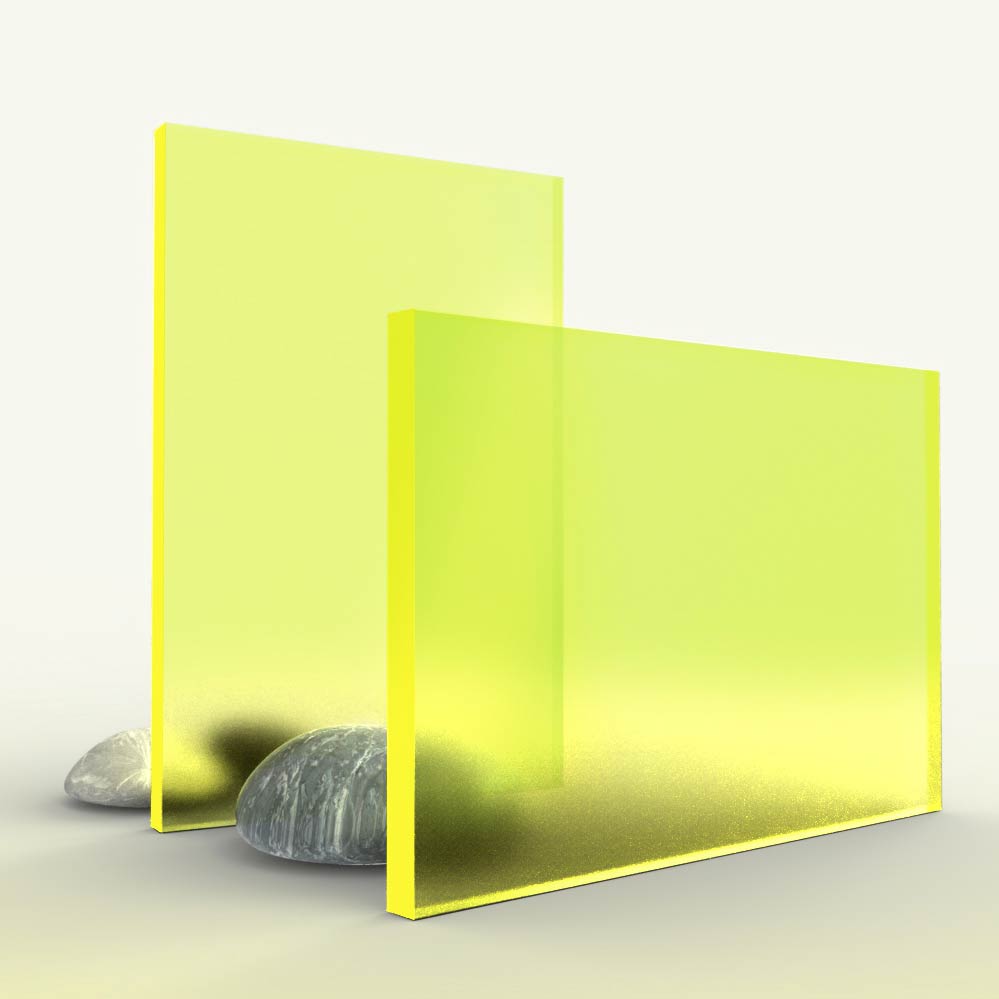

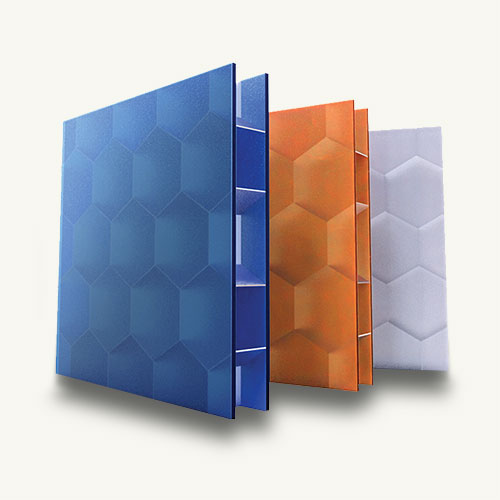

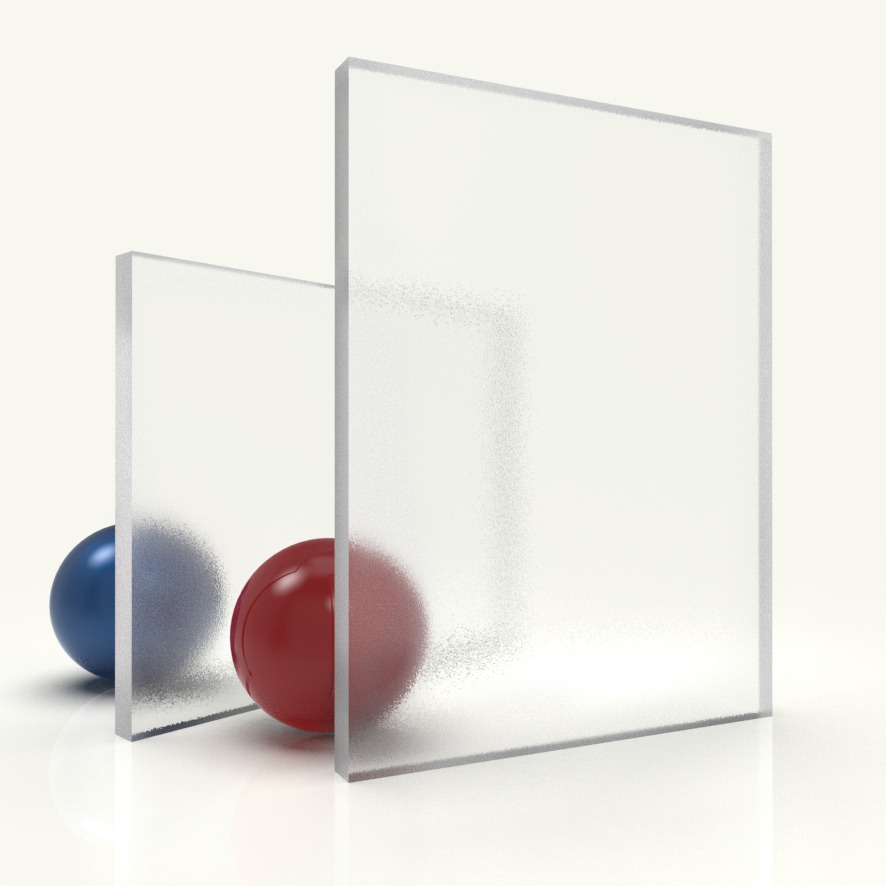

Plexiglass, also known as acrylic glass or polymethyl methacrylate (PMMA), is a transparent thermoplastic material that has gained significant popularity in various industries and settings. It is widely used in construction, automotive, aerospace, and healthcare sectors due to its versatility, durability, and optical clarity. Plexiglass is often preferred over traditional glass due to its lightweight nature and resistance to shattering. When it comes to human health, plexiglass is considered safe. Here are a few reasons why:

- Non-Toxic and Non-Carcinogenic: Plexiglass is made from polymethyl methacrylate (PMMA), which is a non-toxic substance. It does not release any toxic fumes or chemicals that are harmful to humans. Additionally, it is not classified as a carcinogenic material.

- Low Risk of Allergies: Plexiglass is hypoallergenic, meaning it is less likely to cause allergic reactions in individuals who are sensitive to certain materials. This makes it suitable for a wide range of applications, including medical use.

- Low Environmental Impact: Plexiglass is environmentally friendly as it can be recycled and reused. It does not release harmful substances into the air, water, or soil, making it a sustainable choice.

However, it’s important to note that plexiglass, like any other hard material, can pose a physical hazard if broken or misused. Sharp edges or fragments from shattered plexiglass can cause injuries, so it should be handled with care.

Understanding the Chemical Composition and Manufacturing Process of Plexiglass

Plexiglass is derived from petroleum-based raw materials and is manufactured through a polymerization process. The chemical composition of plexiglass includes methyl methacrylate monomers, which are polymerized to form long chains of PMMA. The manufacturing process involves the use of initiators, catalysts, and heat to facilitate the polymerization reaction. The resulting material is then shaped into sheets or molded into various forms.

Potential Health Risks Associated with Exposure to Plexiglass, including Inhalation and Skin Contact

While Plexiglas offers many benefits, there are potential health risks associated with its use. Inhalation of plexiglass dust or fumes during the manufacturing process or when cutting, drilling, or sanding plexiglass sheets can lead to respiratory irritation, coughing, and shortness of breath. Long-term exposure to Plexiglas dust may also cause lung damage and respiratory disorders.

Skin contact with Plexiglas can lead to irritation and redness for people with pre-existing skin conditions or allergies.

And another thing, can Plexiglas have toxic fumes? In answer to this question, it should be said that if it is exposed to very high temperatures such as welding processes or fire, yes it can be harmful, but otherwise this material will never start to evaporate.

Review of Studies and Research on the Effects of Plexiglass on Human Health

Several studies have been conducted to assess the potential health effects of plexiglass exposure. A study published in the Journal of Occupational and Environmental Hygiene found that workers exposed to plexiglass dust had a higher prevalence of respiratory symptoms compared to those not exposed. Another study published in the Journal of Toxicology and Environmental Health reported that plexiglass dust can cause lung inflammation and oxidative stress in animal models.

Regulatory Measures and Guidelines for Safe Use of Plexiglass in Different Industries

To ensure the safe use of plexiglass, regulatory measures and guidelines have been established in various industries. For instance, the Occupational Safety and Health Administration (OSHA) in the United States has set permissible exposure limits for plexiglass dust and fumes in the workplace. Additionally, guidelines for the proper handling, storage, and disposal of plexiglass have been developed by organizations such as the American Conference of Governmental Industrial Hygienists (ACGIH).

Conclusion and Recommendations for Further Research on the Health Risks of Plexiglass

In conclusion, while plexiglass offers numerous advantages, it is important to be aware of the potential health risks associated with its use. Inhalation of plexiglass dust and fumes, as well as skin contact, can lead to respiratory and dermatological issues. Further research is needed to better understand the long-term health effects of plexiglass exposure, especially in occupational settings. It is recommended that individuals working with plexiglass take appropriate safety precautions, such as wearing protective equipment and ensuring proper ventilation. Additionally, continued research and monitoring of plexiglass manufacturing processes and its impact on human health are necessary to ensure the safe use of this material.